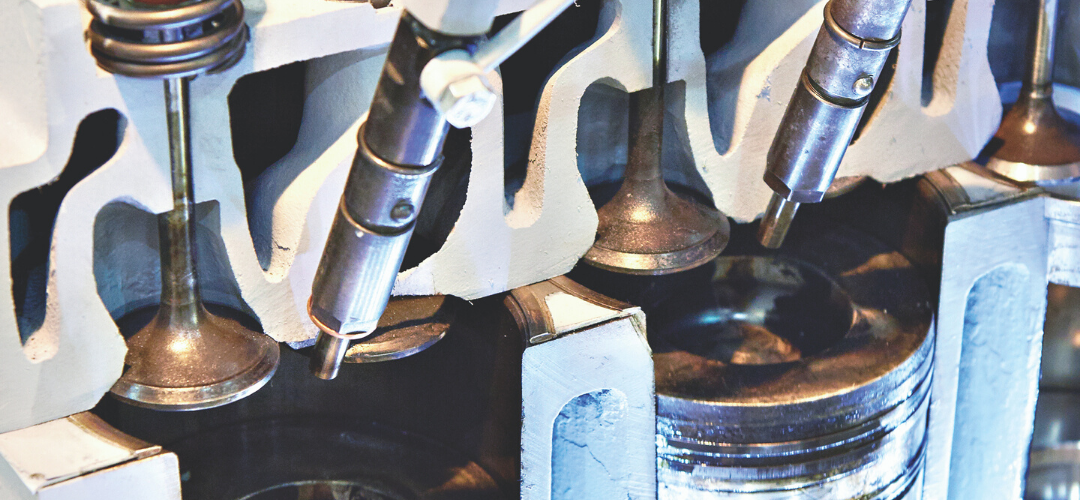

Diesel engines occupy a significant share of the car market today. Due to increasing customer demands for leaner, yet more powerful engines, control and injection systems have become very complex. At the same time, we are faced with a complex exhaust after-treatment system, strictly related to Euro standards.

The participants are taught the principles of operation of these systems, as well as the proper approach to failures that most commonly occur on “Pump-Nozzle” and “Common Rail” injection systems (for instance, high-pressure pump failure, injectors , etc.). In addition, students learn the logical sequence of fault diagnosis of these systems and the correct way to test the components and interpret the results of various measurements.

Seminar goals:

- Participants’ broader insight into the various diesel engine systems and their components

- Better understanding of the impact of their malfunctioning on the vehicle

- Faster and easier diagnosis of vehicle failures through logical sequencing and approach

Contents:

- Operation principles of the pump-nozzle system

- Specifics and problems of pump-nozzle systems

- Development and various designs of pump-nozzle systems

- Testing of mechanical components

- Testing of hydraulic components

- Testing of electrical components

- Operation principle of Common Rail system

- Specifics and problems of Common Rail system

- Development and various designs of Common Rail system

- Exhaust gas treatment

- DPF filter, regeneration, diagnostics

- Testing of mechanical components

- Testing of hydraulic components

- Testing of electrical components